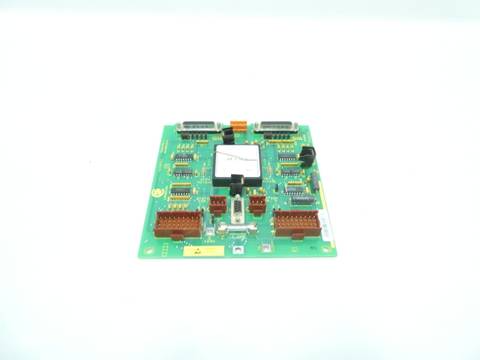

GE IS420UCSBH1A

Understanding the GE IS420UCSBH1A: A Key Component in Industrial Automation

Introduction

At AE Automation CNC Parts, we are dedicated to providing high-quality CNC components and industrial solutions. One critical component that plays an essential role in the realm of electrical engineering and industrial automation is the GE IS420UCSBH1A. This device not only enhances operational efficiency but also contributes significantly to various applications, particularly in renewable energy.

Importance of Electrical Engineering

Electrical engineering is at the heart of modern industrial operations. It involves the study and application of electricity, electronics, and electromagnetism, which are fundamental to the functioning of industrial machinery, communication systems, and renewable energy technologies. The integration of advanced electrical engineering principles is crucial for optimizing performance, ensuring safety, and promoting sustainability in industrial automation.

Technical Specifications: IEC60947-2

The GE IS420UCSBH1A adheres to the IEC60947-2 standard, which governs low-voltage switchgear and controlgear. This standard ensures that the device meets international safety and performance requirements, making it reliable for various applications. Key specifications of the IS420UCSBH1A include:

- Rated operational voltage: Up to 690 V AC

- Rated current: Varies depending on the application

- Short-circuit withstand strength: Ensures protection against short circuits

- Temperature range: -20°C to +60°C, enabling operation in diverse environments

- Degree of protection: IP20, safeguarding internal components from dust and accidental contact

These specifications underscore the versatility and robustness of the GE IS420UCSBH1A, making it a preferred choice for many industrial applications.

Applications in Industrial Automation

The GE IS420UCSBH1A finds extensive applications in industrial automation due to its reliability and efficiency. Here are a few notable applications:

- Process Control: The device is integral to process automation systems, ensuring precise control of various industrial processes.

- Motor Control: It is commonly used in motor control centers, facilitating efficient motor operations in manufacturing plants.

- Safety Systems: The IS420UCSBH1A plays a key role in emergency and safety systems, providing critical fault protection and circuit interruption.

Role in Renewable Energy

The GE IS420UCSBH1A also has significant implications in the renewable energy sector. With the increasing adoption of wind, solar, and other renewable sources, the demand for reliable electrical components has surged. The IS420UCSBH1A contributes to:

- Energy Management Systems: Optimizing energy distribution and usage in renewable installations.

- Wind Turbine Control: Enhancing the efficiency of wind turbine operations through effective electrical control mechanisms.

- Solar Inverters: Ensuring the reliable operation of solar power systems by managing electrical loads and safety features.

These applications emphasize the importance of incorporating reliable components like the GE IS420UCSBH1A in the quest for sustainable energy solutions.

Conclusion

The GE IS420UCSBH1A is more than just a component; it is a vital part of the electrical engineering landscape that supports industrial automation and renewable energy initiatives. By adhering to standards such as IEC60947-2, it ensures safety, efficiency, and reliability in a variety of applications. For those looking to enhance their industrial operations, investing in quality components like the IS420UCSBH1A is crucial.

For more information about quality CNC components and industrial supplies, visit us at AE Automation CNC Parts.

To deepen your understanding of electrical safety standards, refer to the International Electrotechnical Commission.