ABB 1SAP111100R0260: A Comprehensive Guide to Technical Parameters, Industry Applications, and Related Models

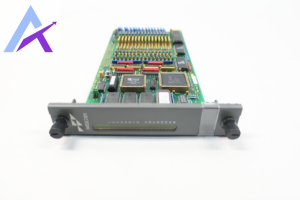

ABB ranks among the top global leaders in industrial automation, consistently delivering cutting-edge solutions for diverse industries. Among their impressive lineup, the ABB 1SAP111100R0260 stands out as a high-performance PLC (Programmable Logic Controller) module designed to tackle complex automation challenges. This article explores the technical parameters of the 1SAP111100R0260, highlights its applications across various industries, and compares it with related models from ABB’s AC500 series. Whether you work as an engineer, a system integrator, or simply seek insights into industrial automation, this guide offers a wealth of information about this versatile product.

Technical Parameters of ABB 1SAP111100R0260

The ABB 1SAP111100R0260 belongs to the AC500 series, specifically the PM582-ETH model, and brings advanced capabilities to industrial control systems. Below, you will find the key technical specifications of this PLC module, presented in a clear and concise table:

| Parameter | Value |

|---|---|

| Processor Type | 32-bit RISC |

| Program Memory | 512 KB |

| Data Memory | 256 KB |

| Digital Inputs | 16 |

| Digital Outputs | 8 |

| Analog Inputs | 4 |

| Analog Outputs | 2 |

| Communication Interfaces | Ethernet, RS232, RS485 |

| Power Supply | 24 V DC |

| Operating Temperature | -25°C to +60°C |

| Dimensions (W x H x D) | 75 x 120 x 85 mm |

| Weight | 350 g |

These specifications empower the 1SAP111100R0260 to handle a wide range of automation tasks, from basic machine control to intricate process automation. For instance, its Ethernet connectivity enables seamless integration into modern industrial networks, facilitating real-time data exchange and remote monitoring.

Breaking Down the Technical Parameters

Processor Type: The 32-bit RISC processor drives fast execution of control logic, delivering real-time responses to input signals. This capability proves essential for applications requiring high-speed processing, such as motion control or rapid data logging.

Program Memory: With 512 KB of program memory, the 1SAP111100R0260 supports complex automation programs, including multiple tasks and extensive logic operations. Engineers can leverage this capacity to implement advanced control algorithms and adapt to evolving project needs.

Data Memory: The 256 KB data memory stores large datasets, such as process variables, historical data, and configuration settings. This feature ensures efficient data management, enabling smooth operation within the control system.

Inputs and Outputs: The module offers 16 digital inputs and 8 digital outputs, complemented by 4 analog inputs and 2 analog outputs. This combination allows engineers to control both discrete and continuous processes, making the 1SAP111100R0260 adaptable to diverse applications.

Communication Interfaces: Featuring Ethernet, RS232, and RS485 interfaces, the 1SAP111100R0260 connects effortlessly with other devices, such as HMIs (Human-Machine Interfaces), SCADA systems, and additional PLCs. This connectivity fosters integrated automation solutions across industrial setups.

Power Supply and Environmental Conditions: The module runs on a 24 V DC power supply and operates within a temperature range of -25°C to +60°C. Consequently, it thrives in harsh industrial environments, from frigid outdoor installations to warm factory floors.

For more in-depth specifications, explore the official ABB product page.

Industry Applications of ABB 1SAP111100R0260

The adaptability of the ABB 1SAP111100R0260 positions it as a prime choice for numerous industries. Below, we examine key sectors where this PLC module shines, showcasing its real-world impact:

- Manufacturing: In manufacturing facilities, the 1SAP111100R0260 controls production lines, manages robotic systems, and optimizes machinery operation. Its rapid processing speed and versatile I/O options enable precise control over manufacturing processes. For example, in an automotive assembly plant, the module synchronizes robots welding car bodies, oversees paint sprayers, and monitors quality inspection systems. Additionally, its Ethernet connectivity integrates with the plant’s MES (Manufacturing Execution System), delivering real-time production data to managers.

- Packaging: The PLC module excels in packaging automation, coordinating conveyor belts, filling machines, and labeling systems. Its reliability guarantees consistent product quality and high throughput. In a food packaging plant, for instance, the 1SAP111100R0260 manages the entire process—filling containers, sealing them, and applying labels—ensuring both efficiency and precision.

- Material Handling: In warehouses and distribution centers, the 1SAP111100R0260 oversees automated storage and retrieval systems (AS/RS), conveyor systems, and sorting machines, streamlining logistics operations. Its ability to manage multiple inputs and outputs supports complex material flow systems, minimizing downtime and boosting productivity.

- Building Automation: For smart buildings, this PLC module controls HVAC systems, lighting, and security setups, enhancing energy efficiency and occupant comfort. In a commercial building, the 1SAP111100R0260 integrates with building management systems to monitor and adjust environmental conditions in real-time, cutting energy costs while maintaining optimal settings.

- Water and Wastewater Treatment: The module monitors and controls pumps, valves, and treatment processes, ensuring compliance with environmental standards and efficient resource use. In a municipal water treatment facility, the 1SAP111100R0260 manages the entire process—from water intake to distribution—delivering safe, clean water to communities.

These examples underscore the flexibility of the 1SAP111100R0260 across varied industrial settings. Its durable design and broad operating temperature range make it suitable for both indoor and outdoor environments.

To discover more about how ABB PLCs transform industries, check out our products page.

Real-World Examples of ABB 1SAP111100R0260 in Action

In a textile manufacturing plant, the 1SAP111100R0260 controls spinning machines and weaving looms, ensuring consistent thread tension and fabric quality. Its analog inputs monitor tension sensors, while its digital outputs adjust motor speeds, maintaining production efficiency.

Similarly, in a pharmaceutical packaging line, the module synchronizes high-speed filling machines with capping and labeling systems. Its real-time processing capabilities prevent bottlenecks, ensuring that products meet stringent regulatory standards.

In a logistics hub, the 1SAP111100R0260 manages a network of conveyor belts and robotic arms, sorting packages based on destination codes. Its Ethernet interface connects with warehouse management software, enabling seamless tracking and reporting.

Related Models and Their Parameters

ABB provides a diverse range of PLC modules within the AC500 series, each tailored to specific application demands. Below, we compare the 1SAP111100R0260 (PM582-ETH) with two related models: the PM571-ETH and the PM591-ETH, using a detailed table:

| Feature | PM571-ETH | PM582-ETH (1SAP111100R0260) | PM591-ETH |

|---|---|---|---|

| Program Memory | 256 KB | 512 KB | 1024 KB |

| Data Memory | 128 KB | 256 KB | 512 KB |

| Digital Inputs | 8 | 16 | 32 |

| Digital Outputs | 4 | 8 | 16 |

| Analog Inputs | 2 | 4 | 8 |

| Analog Outputs | 1 | 2 | 4 |

| Communication | Ethernet, RS232 | Ethernet, RS232, RS485 | Ethernet, RS232, RS485, CAN |

| Power Supply | 24 V DC | 24 V DC | 24 V DC |

This table reveals that the PM582-ETH strikes a balance between performance and capacity, ideal for medium-sized applications. Meanwhile, the PM571-ETH targets smaller systems, and the PM591-ETH addresses larger, more complex automation needs.

Comparing the Models

PM571-ETH: With 256 KB of program memory and fewer I/Os, this model suits simple applications, such as controlling a single machine or a small conveyor system. Its compact size and cost-effectiveness attract users tackling entry-level automation projects.

PM582-ETH (1SAP111100R0260): This model offers a versatile mix of features for medium-scale applications, like packaging lines or material handling systems. Its additional RS485 interface enhances connectivity options, making it a flexible choice for integrated setups.

PM591-ETH: Engineered for large-scale automation, this model provides 1024 KB of program memory and expanded I/O capabilities. It excels in controlling entire production lines or complex process plants, where extensive data processing and multiple communication protocols prove necessary.

For a full overview of ABB AC500 series PLCs, visit the ABB AC500 series page.

How to Program the ABB 1SAP111100R0260

Engineers program the 1SAP111100R0260 using ABB’s Automation Builder software, which provides an intuitive interface for developing, testing, and debugging automation programs. This software supports multiple programming languages—ladder logic, function block diagram, and structured text—accommodating various preferences and project requirements.

Furthermore, Automation Builder integrates with other ABB tools, such as Drive Composer for motor control, streamlining the development process. This integration enables engineers to manage multiple project components from one platform, saving time and boosting system reliability.

For beginners, the software includes extensive documentation and tutorials, easing the learning process. Additionally, ABB offers training programs and support services to help users unlock the full potential of their automation solutions.

Key Features and Benefits of ABB 1SAP111100R0260

Several attributes distinguish the ABB 1SAP111100R0260 as a premier choice for automation professionals:

- Reliability: ABB’s commitment to quality ensures that the 1SAP111100R0260 performs consistently in demanding environments. Its rugged design withstands harsh conditions, minimizing downtime risks.

- Scalability: As part of the AC500 series, the 1SAP111100R0260 supports easy expansion. Users can add I/O modules or upgrade to higher models as their needs evolve, safeguarding their investment.

- Advanced Features: The module’s Ethernet connectivity, diverse communication interfaces, and ample memory capacity enable sophisticated control strategies and compatibility with Industry 4.0 technologies.

- Support and Resources: ABB provides comprehensive support, including detailed manuals, online resources, and customer service, empowering users to resolve issues quickly and optimize their systems.

Moreover, the 1SAP111100R0260 delivers excellent value, blending high performance with competitive pricing. This combination appeals to both small businesses and large enterprises aiming to enhance their automation capabilities.

Conclusion

The ABB 1SAP111100R0260 (PM582-ETH) emerges as a robust and adaptable PLC module, perfectly suited to the demands of modern industrial automation. Its impressive technical parameters, extensive industry applications, and synergy with other AC500 series models make it an outstanding option for engineers and system integrators. Whether you aim to automate a manufacturing line, streamline a packaging system, or enhance building automation, this PLC module delivers the reliability and performance you require.

For more details or to purchase the ABB 1SAP111100R0260, visit aecncparts.com.

Leave a comment

Your email address will not be published. Required fields are marked *